Bike fleet solutions

Circular economy in action

Smart solutions for bicycle fleets

Onze expertise in het herproduceren van fietsen kan waardevol zijn voor eigenaren van fietsenvloten, zoals hotels, bedrijven en fietsverhuurders. Door onze circulaire aanpak helpen we ze hun afhankelijkheid van grondstofprijzen te verminderen, hun eigen footprint te reduceren en een met een do-good story hun imago een boost te geven.

CIRCULAR DESIGN

Where others see a discarded bike with broken parts and full of rust, we see valuable materials. Circular design is a matter of perspective and needs us all to re-think the way we make stuff.

Designing products that can be 'made to be made again'.

- Ellen MacArthur Foundation

The entire Roetz concept is based on 'remanufacturing'. Founder Tiemen ter Hoeven was inspired by the automotive industry, where remanufacturing is common practice.

Living in Amsterdam, Tiemen litterally stumbled over discarded bikes. Roughly one million bikes are thrown away in the Netherlands annually. A future-proof business idea was born: by re-working parts and materials that are too good to be thrown away, we give them a second life. Today, we achieve 30-40% circularity with our Roetz collection and 70% by remanufacturing the OV-fiets bike fleet. In 2016, we saved more than 20 tons of valuable materials with our circular production method. Do you like the sound of that? Let's get in touch!

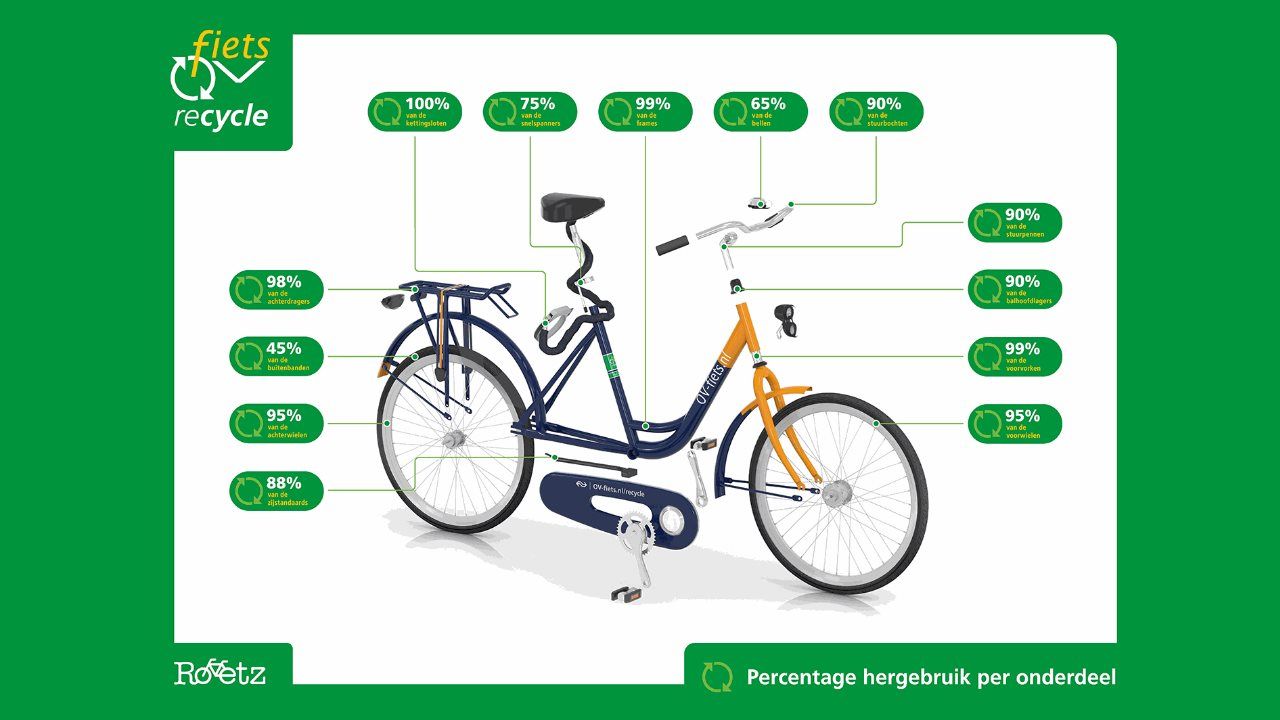

case: OV-FIETS recycle

For our customer, Roetz re-manufactures over 1.000 bikes a year in the Amsterdam-based Fair Factory. This is the largest re-manufacturing program for bikes ever in the Netherlands.

We are proud that the collaboration between NS and Roetz resulted in a reduced footprint by 14,5 ton raw materials by re-using 70% of the old bike. Several technical and ergonomical improvements have been implemented and NS is less dependant on increasing raw material prices. Most of all, we are proud to be able to give 12 Roetz makers the opportunity to learn a new profession through the production of this fleet.