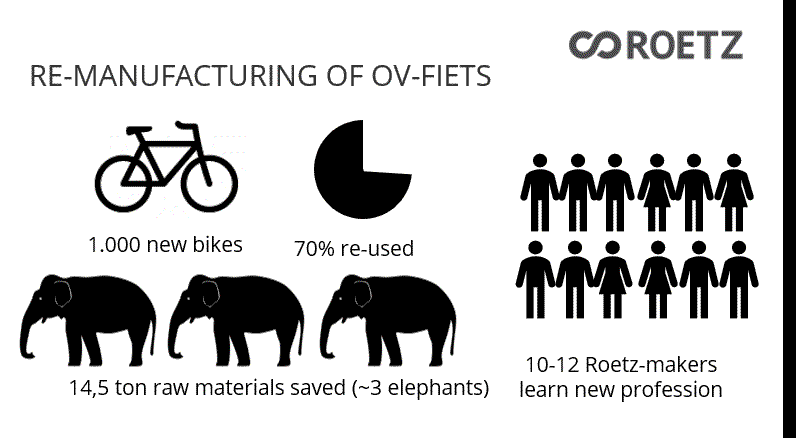

Every Dutch person knows the OV-fiets, a bike rental service by the Dutch Railway NS Nationale Spoorwegen. An enourmous fleet of roughly 8.000 bikes are available to private and business users alike who make around 2 million trips a year. An OV-fiets has a life-cycle of four years, which means that 2.000 bikes need to be replaced annually. Roetz-Bikes re-manufactures 1.000 OV-fietsen a year in the Amsterdam-based Fair Factory. This is the largest re-manufacturing program for bikes ever in the Netherlands. NS plans to re-manufacture the lion-share of the end-of-life bikes eventually.

In 2015, the NS and Roetz-Bikes partnered up to develop the OV-fiets Re-cycle program. Inspired by the automotive industry, the core processes were translated and optimized for bike fleets. The main goal was to implement circular and socially responsible production method.

A FIVE-STEP APPROACH

So how do we transform a discarded bike and turn it into a shinny new one re-using 70% of the original bike?

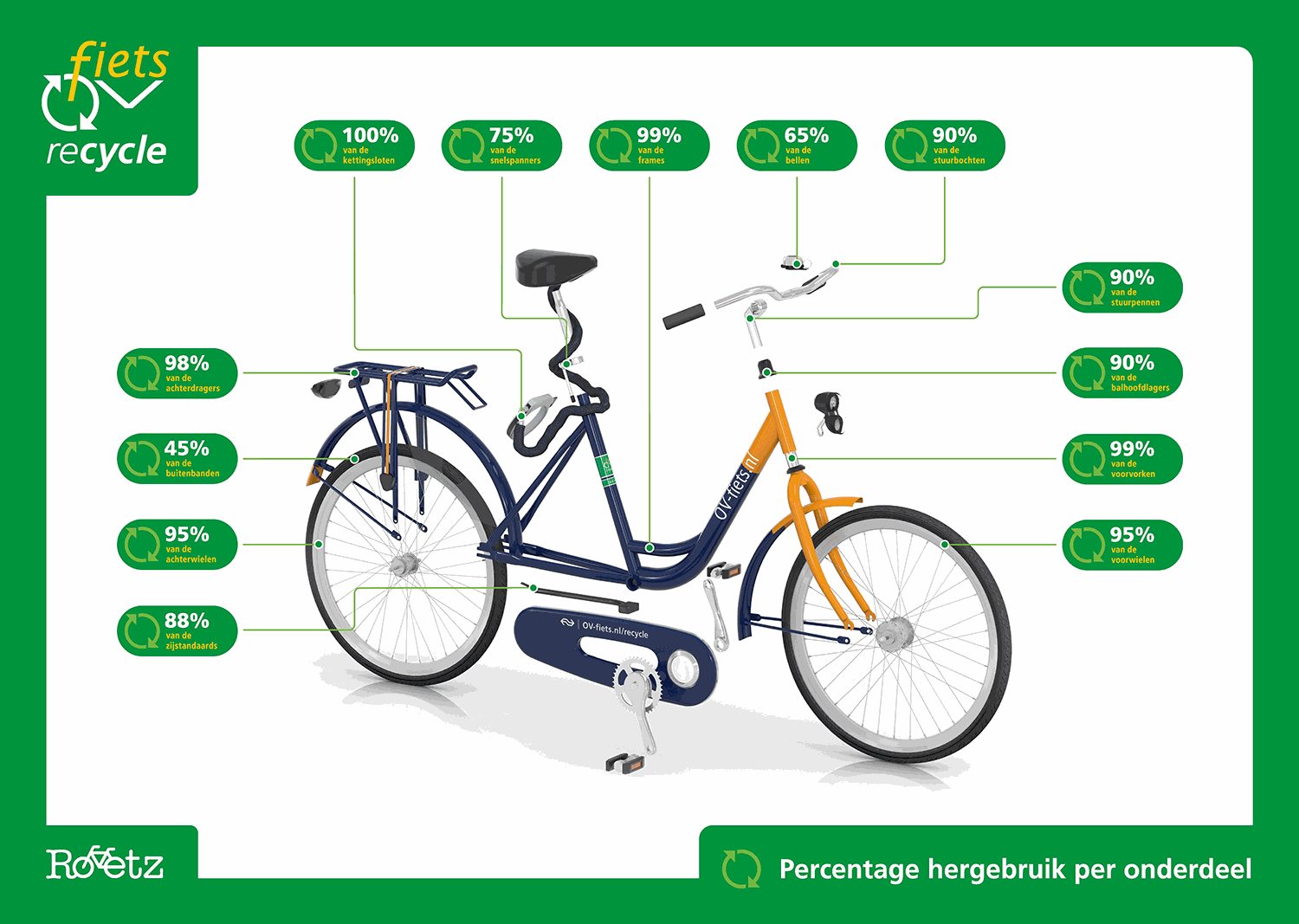

We collect discarded bikes on a regular basis and perform an initial screening. Discarded OV-fietsen arrive at our workplace and are dismantled in more than 100 parts. We sort-out and re-cycle all parts unsuitable for a new life-cycle. Re-usable parts are thouroughly checked and professionally cleaned. After the original lacquer of frames and carriers is removed, a new protective coating is applied for a fresh and clean look. Where possible, we repair parts. We can even fix crocked wheels by aligning them again. Fenders and chain guards do not make a next life-cycle and are replaced by new parts. Finally, the OV-fietsen are assembled in our Fair Factory by a team of bike technicians, one-by-one and by hand.

SOCIALLY RESPONSIBLE

This re-manufacturing program is not only sustainable, but also socially responsible. The Roetz makers a men and women with poor job prospects which we train to become skilled bike technicians.

ACHIEVEMENTS

Several results make us proud:

• 70% of old bike is re-used; reduced footprint by 14,5 ton raw materials

• Less dependancy on raw material prices

• 10 improvemens have been implemented

• 10-12 Roetz-makers have the opportunity to learn a new profession

De herproductie van de OV-Fiets heeft zich bewezen als professioneel alternatief voor nieuwe fietsen. Roetz-Bikes zorgt voor fietsen van uitstekende kwaliteit én voor een goede prijs. En niet onbelangrijk: met deze duurzame aanpak besparen we grondstoffen!

CAROLA WIJDOOGEN, DIRECTEUR DUURZAAM ONDERNEMEN NEDERLANDSE SPOORWEGEN

WANT TO DIVE INTO DETAILS?

Do you see the benefits of reproducing your bike fleet instead of replacing it?